- August 12, 2023

- Posted by: portable line boring & welding machines

- Category: Line Boring Machines About

Unlocking the Power of Portable Line Boring Machines: A Comprehensive Guide

Portable line boring machines are a versatile and indispensable tool for precision machining and drilling tasks. If you’re wondering how to harness the full potential of these powerful devices, you’ve come to the right place. In this guide, we’ll walk you through the essential steps to make the most out of your portable line boring machine, ensuring top-notch performance and optimal results.

-

Cylinder Valve line boring Understand Your Machine: Before diving into operation, familiarize yourself with your portable line boring machine. Study the user manual carefully, which provides valuable insights into its features, functions, and safety guidelines. A well-informed user can achieve better outcomes and prevent any mishaps during operation.

- Safety First: As with any equipment, safety should be your top priority. Ensure all operators and staff are equipped with the necessary safety gear, such as goggles and gloves. Never operate the machine without reading and understanding the safety instructions outlined in the user manual.

- Inspect and Prepare the Work Area: Before using the portable line boring machine, thoroughly inspect the work area. Remove any debris or obstacles that could hinder the operation. Ensure the machine is set up on a stable and level surface to prevent accidents during use.

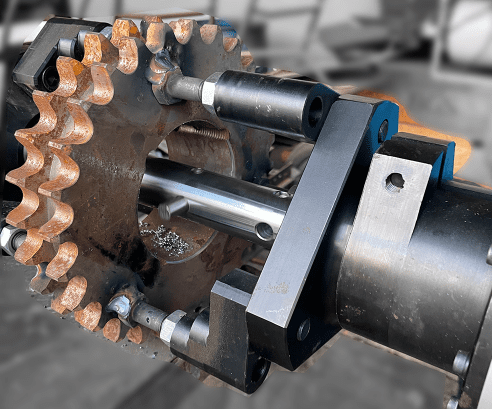

- Properly Secure the Workpiece: To achieve accurate results, secure the workpiece firmly in place. A properly anchored workpiece minimizes vibrations and allows for smooth and precise boring. Use clamps or fixtures to hold the workpiece securely during the operation.

- Choose the Right Cutting Tools: Selecting the appropriate cutting tools is crucial for optimal performance. Consider factors such as material type, tolerance requirements, and bore diameter when choosing the cutting tools. High-quality, sharp tools enhance efficiency and ensure clean cuts.

- Begin Boring Process: Start the portable line boring machine and slowly introduce the cutting tool into the workpiece. Use a steady and controlled motion to maintain accuracy. Regularly check the progress and make adjustments as needed.

- Maintain Proper Coolant Flow: Cooling the cutting area is essential to prevent overheating and extend tool life. Ensure a consistent and appropriate coolant flow throughout the boring process. This helps maintain the quality of the machined surface.

- Monitor Performance: Keep a close eye on the machine’s performance and the quality of the boring. If you notice any irregularities or deviations, stop the operation immediately and investigate the issue. Addressing problems early can save time and resources.

- Utilize Training Resources: If you or your staff are new to using portable line boring machines, consider watching instructional videos or seeking guidance from experienced users. Proper training enhances skills and confidence, leading to better results.

- Regular Maintenance: To ensure the longevity and consistent performance of your portable line boring machine, adhere to the recommended maintenance schedule. Keep the machine clean, lubricated, and inspect it regularly for any signs of wear or damage.

Which is more important?

By following these guidelines, you can master the art of using portable line boring machines to their full potential. Achieve precision, boost productivity, and unlock a world of possibilities for machining and drilling tasks. With the right knowledge and practice, your portable line boring machine can become an invaluable asset to your operations in Turkey or anywhere in the world.

[…] guarantees dependable performance, even in the most demanding situations. Employing a portable line boring machine provides numerous benefits, such as on-site accuracy, cost efficiency, versatility, ease of use, […]