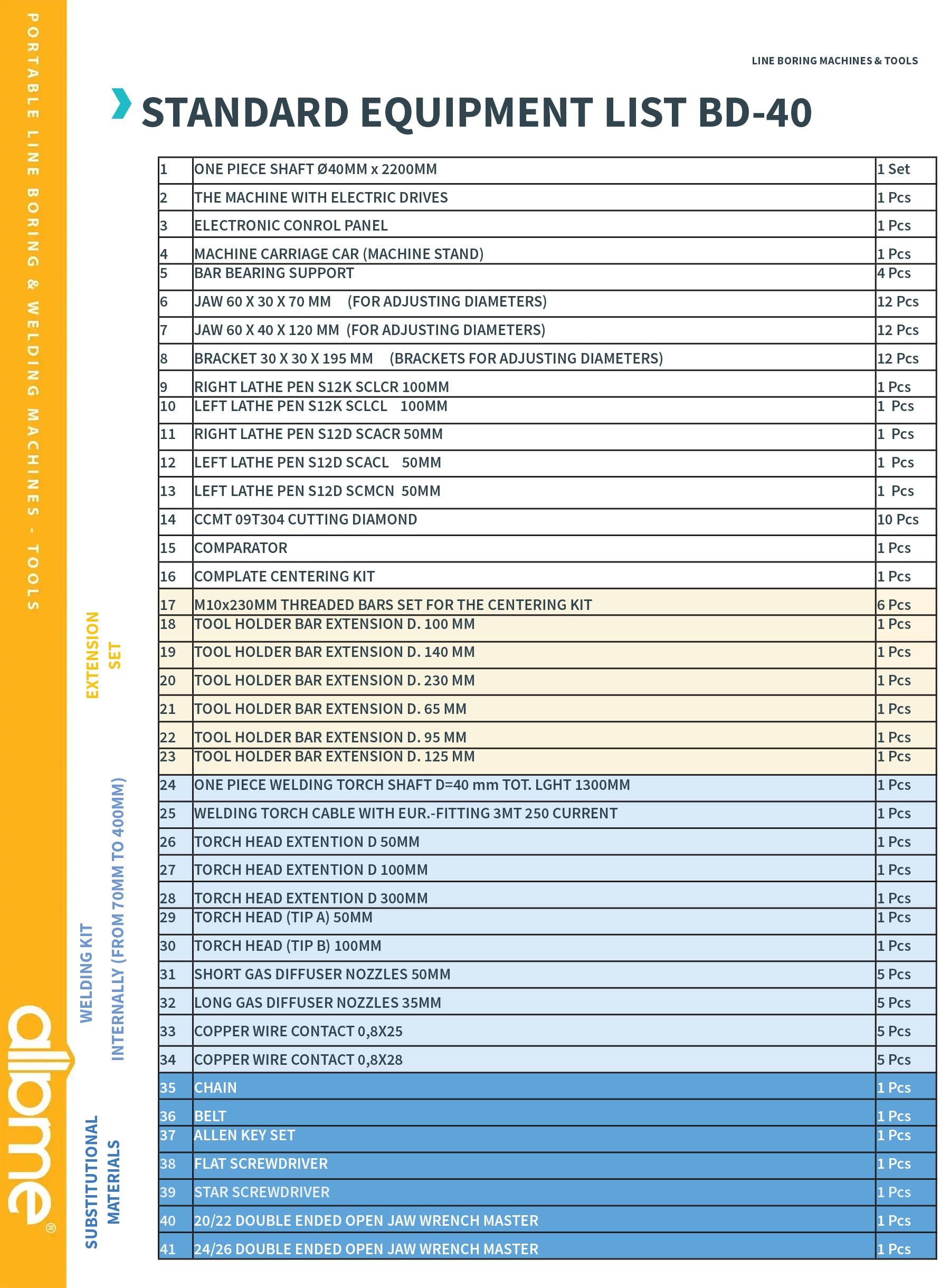

Portable Line Boring Machine BD-40

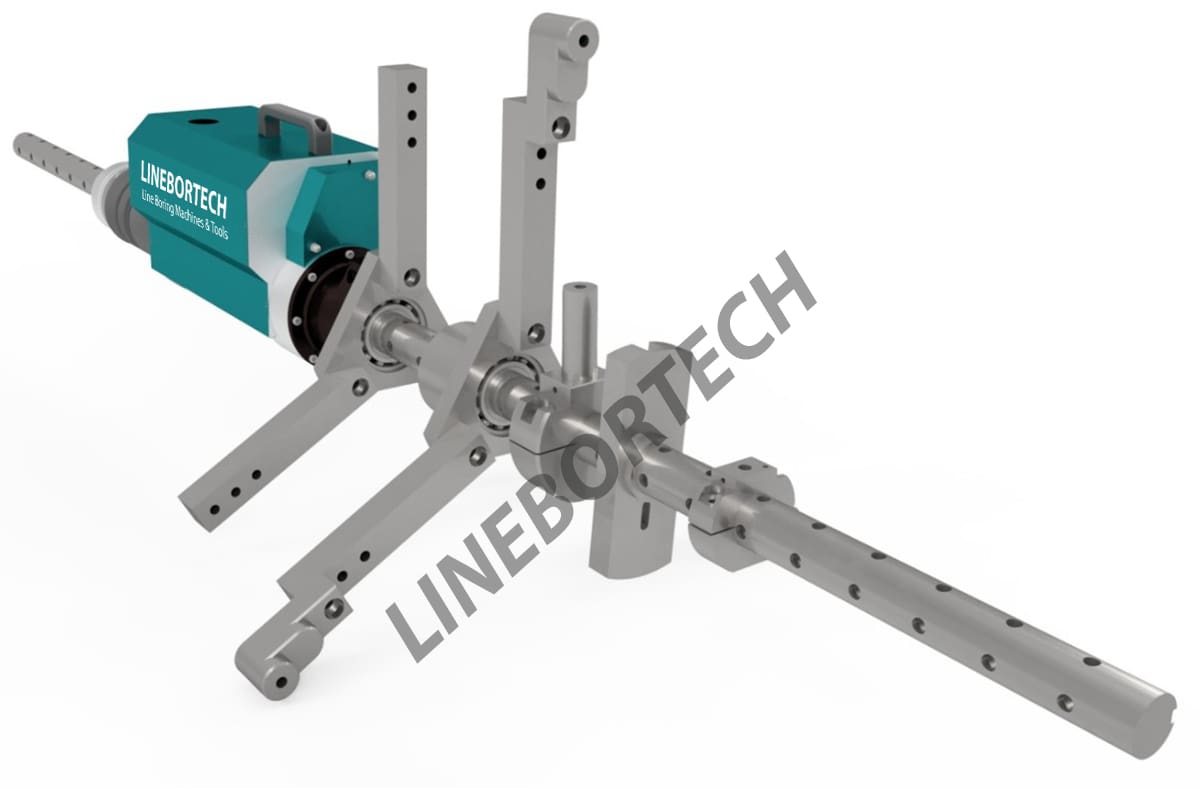

Portable line boring welding machine are mounted on the workpiece with a three-point carrier material. For example; If the connection holes of an excavator bucket are to be machined. They are mounted on the workpiece of the portable line boring welding machine with various connection equipment so as not to cause axis misalignment.

The machine operates with the movement of the electric servomotor located on it. Such portable benches are used for workpieces that are too large to be brought to the workshop and which are very costly to move and are located at distant places.

With the portable boring machines we produce, we are increasing the advantages of fast service and capability to all the companies that provide heavy service in the metal industry.

The portable line boring welding machine with three great feature;

You can transform your technical capability into a fast, productive and quality situation as you want.

Some features that make portable boring machine different

The equipment and consumables used in our products are chosen in the best quality and our valued customers will feel the difference of this quality for a long time.

- More powerful and trouble-free with the engine-coupled transmission.

- The gears are hardened with 55 HRC and are made more durable.

- Easy installation due to the structure consisting of light and durable materials.

- The electronic panel allows you to control the sensitivity and power at the same time.

- High standard modular design for ease of installation and transport.

- We produce reliable products with 600 hours working guarantee.

Technical information and evaluation

Portable boring machine is widely used in many areas, cranes, excavators, bulldozers, tractors, offshore platforms, in ship machines and storage tanks and so on.

Bar shaft diameter: 40 mm.

In-hole machining diameter (boring): From 42mm to 400mm.

In-hole machining diameter (welding): From 65mm to 400mm.

Bar shaft turn motor:

AC Servo Motor – Voltage:230VAC

Min: 0.20 Rpm. (rev/min.) – Max: 225 Rpm. (rev/min.)

Bar shaft Forward and reverse motion motor:

DC Servo Motor – Power:90Watts, Voltage:24VDC

Speed Range min: 0.05mm/min – max: 95mm/min

Stroke : 230mm.

● Wide speed range, flat torque

● Excellent speed stability

● Compact and high power

● High efficiency and energy-saving

Working voltage:

230VAC 50/60 hz – 10 Amp.

Control circuit devices and switching elements :

● Start / Stop switch

● Emergency button

● Toggle switches(Right left rotation switch/stepping)

● Emergency button

● Speed/cyclic control knob

● Move back and forth stepping switch

● Fast motion button

● Reset button

● Control screen

LINEBORTECH Portable Line Boring Welding Machine delivers your projects on time and makes quality much easier; With our professional technical machines, you can make your sensitive operations much easier. You will confirm the quality of all the equipment we use.

LINEBORTECH Portable Line Boring & Welding Machine delivers your projects on time and makes quality much easier; With our professional technical machines, you can make your sensitive operations much easier. You will confirm the quality of all the equipment we use.

Exploring the Equipment of Portable Line Boring Welding Machines for Efficient Excavator Repairs

Introduction:

Portable line boring and welding machines are indispensable tools in the field of equipment repair, particularly for excavators. These machines combine the capabilities of line boring and welding to efficiently restore and repair large bores. In this article, we will delve into the equipment and components that make up a portable line boring and welding machine, highlighting their importance in the excavator repair process.

Boring Bar Assembly:

The heart of a portable line boring welding machine is the boring bar assembly. This component consists of a rigid bar with cutting tools attached to it. The cutting tools are responsible for removing material and restoring the damaged bore to its original specifications. Boring bar assemblies come in various sizes to accommodate different bore diameters and lengths, ensuring versatility for a wide range of repair applications.

Welding Head Assembly:

The welding head assembly is a crucial component of portable line boring and welding machines. It enables the machine to perform not only line boring but also welding repairs. The welding head assembly consists of a welding torch or gun that allows for the deposition of filler material to restore worn or damaged surfaces. It ensures the seamless integration of the line boring and welding processes, providing comprehensive repair solutions.

Power Unit:

The power unit is responsible for providing the necessary energy to drive the boring and welding operations. Portable line boring and welding machines are typically powered by hydraulic systems or electric motors. Hydraulic power units utilize hydraulic fluid to generate the required force for the cutting and welding actions. Electric power units, on the other hand, rely on electricity to drive the machine. The power unit selection depends on factors such as the specific application, the desired level of precision, and the available power sources.

Control System:

Modern portable line boring welding machine often incorporate advanced control systems. These systems enhance precision and ease of operation, allowing operators to control parameters such as feed rate, spindle speed, and welding parameters. User-friendly interfaces, digital readouts, and intuitive controls enable operators to monitor and adjust settings for optimal results. The control system plays a vital role in ensuring accurate and efficient repairs, reducing human error and enhancing productivity.

Stabilization Equipment:

Stabilization equipment is crucial for maintaining stability and ensuring precise machining during the repair process. It includes components such as support brackets, clamps, and anchoring systems. These elements secure the machine in place, minimizing vibrations and maintaining alignment while performing line boring and welding operations. Stabilization equipment contributes to the overall accuracy and quality of the repairs.

Safety Features:

Portable line boring and welding machines are equipped with safety features to protect operators and maintain a safe working environment. Common safety features include emergency stop buttons, protective covers, safety interlocks, and operator shields. Adhering to proper safety protocols and utilizing the provided safety features is essential to prevent accidents and injuries during the repair process.

Conclusion:

Portable line boring welding machines offer a comprehensive solution for excavator repairs, combining line boring and welding capabilities in a single device. The equipment and components discussed in this article, including the boring bar assembly, welding head assembly, power unit, control system, stabilization equipment, and safety features, collectively contribute to the machine’s efficiency, accuracy, and safety. When selecting a portable line boring welding machine, consider the specific requirements of your excavator repair work, ensuring that the equipment meets your needs for successful and productive repairs. With the right machine and equipment, you can restore bores and surfaces effectively, extending the lifespan and functionality of your valuable excavator equipment.