- October 28, 2023

- Posted by: portable line boring & welding machines

- Category: Line Boring Machines About

Optimizing Welding Processes with Portable Line Boring Machines

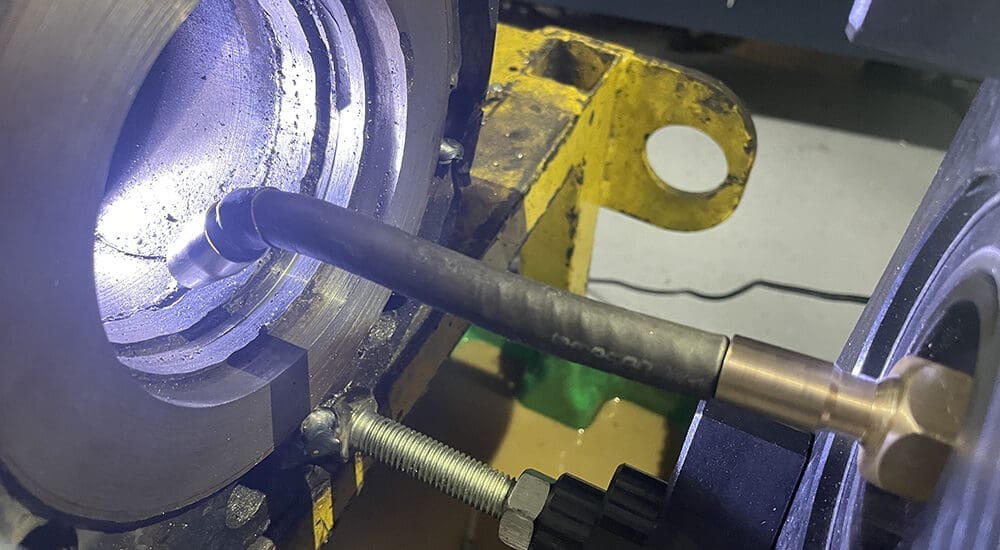

In the realm of machining and welding, the seamless integration of portable line boring machines can significantly enhance the welding process. These versatile tools not only facilitate precision drilling and boring but also play a pivotal role in ensuring the welding process is executed with utmost accuracy. Here’s a comprehensive guide on how to adjust the welding process with portable line boring machines to achieve optimal results.

-

Mobile line boring machine welding equipments Understanding Welding Types: Before initiating the welding process, it’s crucial to comprehend various welding types, such as MIG, TIG, and stick welding. This understanding allows for informed adjustments and ensures compatibility with the capabilities of portable line boring machines.

- Assessing Welding Speed: Determine the ideal welding speed based on the material being welded and the desired joint quality. Adjust the portable line boring machine’s settings to synchronize with the appropriate welding speed, thus maintaining the integrity of the welding process.

- Selecting Suitable Welding Tools: Choosing the right welding tools, including the welding wire and appropriate welding electrodes, is vital for seamless integration with the portable line boring machines. Opt for tools that complement the specific requirements of the welding task at hand.

- Calibrating Bore Diameter: Prior to the welding process, calibrate the bore diameter using the portable line boring machine to ensure the dimensions of the borehole are compatible with the welding joint. This step is crucial for achieving a secure and robust welding connection.

- Adjusting Welding Techniques: Fine-tune the welding techniques to match the capabilities of the portable line boring machines. This may involve making adjustments to the angle of approach, the welding speed, and the intensity of the welding arc to ensure a uniform and strong weld.

- Integrating User Manual Guidelines: Refer to the user manual provided by the manufacturers of both the welding equipment and the portable line boring machine. Adhering to the guidelines outlined in the user manual ensures the correct configuration and alignment of the equipment for an effective welding process.

- Optimizing Performance with Staff Training: Train your staff and welding operators in the effective use of the portable line boring machines in conjunction with the welding process. This training enhances their understanding of how to adjust and optimize the welding process for improved efficiency and quality.

- Utilizing Online Resources: Take advantage of online instructional videos and forums that provide insights and practical tips on integrating welding processes with portable line boring machines. These resources offer valuable guidance and real-world experiences from industry experts and fellow users.

- Ensuring Material Compatibility: Verify that the materials being welded are compatible with the capabilities of the portable line boring machines. Understanding the structural properties of the materials helps in making informed adjustments to the welding process, ensuring a secure and long-lasting weld.

- Regular Maintenance and Inspection: Conduct routine maintenance and inspections of both the welding equipment and the portable line boring machine to ensure optimal performance. Regular upkeep prevents unexpected downtimes and maintains the efficiency of the welding process.

Welding is important!

By following these guidelines, businesses in Turkiye and beyond can optimize their welding processes by seamlessly integrating portable line boring machines. This integration not only enhances the overall efficiency of the welding operation but also contributes to the production of robust and high-quality welds, fostering the success and growth of the business.