- June 14, 2023

- Posted by: portable line boring & welding machines

- Category: Line Boring Machines About

Portable line boring machine is a facing lathe tool used for onsite machining of large and heavy equipment, such as engine blocks, turbines, and other industrial components. It allows for precise and accurate restoration of damaged or worn-out bores.

The face turning apparatus is an important component of a portable line boring machine. Its primary function is to machine the face or surface of the bore end. This apparatus enables the operator to achieve a smooth and flat finish, ensuring proper sealing and alignment of mating components.

The face turning apparatus typically consists of the following key elements:

Facing Lathe Tool: This is the cutting tool that removes material from the bore face. It can be a single-point tool, typically made of high-speed steel (HSS) or carbide, or a multiple-point cutting tool.

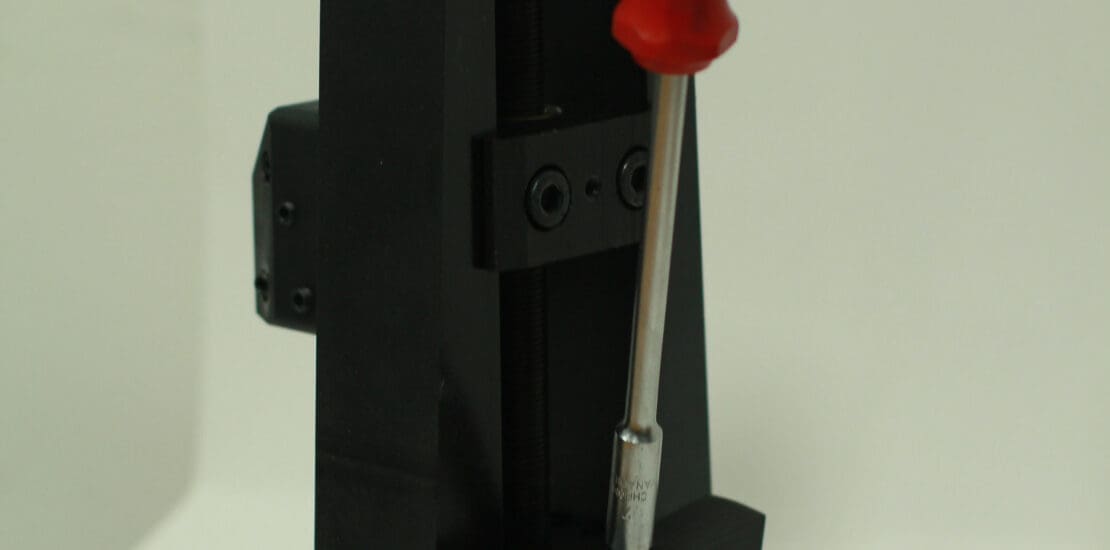

Tool Holder: The tool holder holds the facing tool securely in place and provides the necessary support for the cutting operation. It is designed to withstand the cutting forces and vibrations generated during the machining process.

Feed Mechanism: The feed mechanism allows the operator to control the movement of the facing tool across the bore face. It enables precise adjustment of the cutting depth and feed rate, ensuring accurate machining and a consistent finish.

Positioning System: The face turning apparatus is equipped with a positioning system that allows the operator to accurately position the facing tool at the desired location on the bore face. This can be achieved through various mechanisms, such as manual cranks, micrometer dials, or digital readouts.

Clamping System: To ensure stability and rigidity during the machining process, the face turning apparatus is often equipped with a clamping system. This system securely holds the portable line boring machine in place, preventing any movement or vibration that could affect the machining accuracy.

The face turning apparatus plays a crucial role in achieving precise and high-quality machining results with a portable line boring machine. It enables the operator to restore bores to their original specifications, ensuring proper functioning and longevity of the machined components.