Portable Flange Facer

Unveiling the Power of Portable Flange Facing Machines: Precision on the Go

Portable flange facing machines have become the go-to solution for industries demanding precision and mobility in their machining processes. Whether you’re in anywhere worldwide, understanding the capabilities of these versatile tools is key to unlocking efficient flange turning and maintenance. Let’s delve into what makes portable flange facing machines a game-changer in the realm of machining.

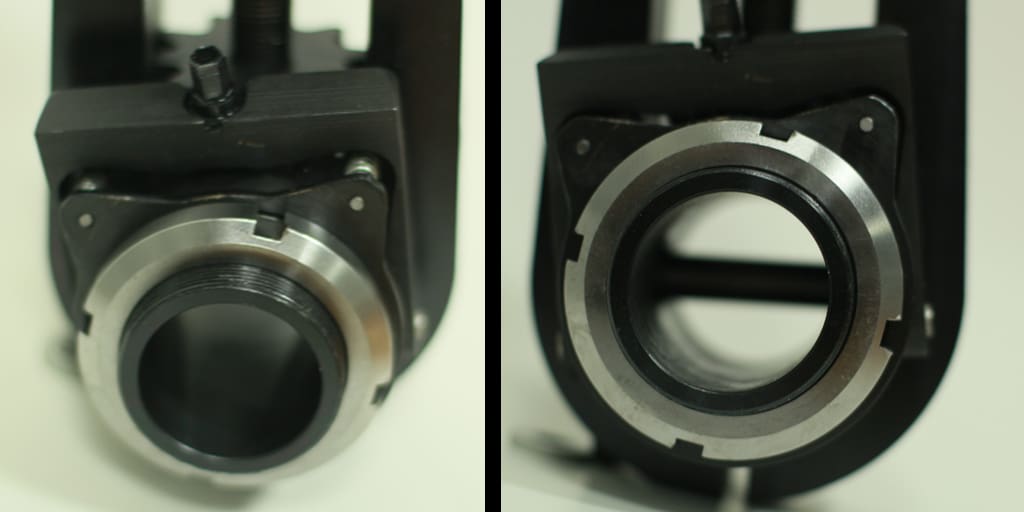

What is a Portable Flange Facing Machine?

A portable flange facing machine, also known as a flange facer, is a specialized tool designed for on-the-spot machining of flanges. These machines offer the flexibility and convenience of being easily transported to the work site, eliminating the need for complex setups and transportation of heavy equipment.

Precision Flange Turning on the Move

Flange facing involves the precision machining of flanges to achieve smooth and accurate surfaces, ensuring proper alignment and sealing. Portable flange facing machines excel in this task, allowing operators to turn, mill, and resurface flanges with precision, regardless of the location or environmental challenges.

Mobile Flange Facing Machines: Key Features

These machines boast features that make them stand out in the world of machining:

- Portability: The defining feature. These machines are designed for easy transport, enabling on-site machining without the hassle of moving heavy equipment.

- Durability and Strength: Built to withstand demanding conditions, portable flange facing machines are constructed with robust materials, ensuring longevity and reliability in diverse work environments.

- User-Friendly Operation: With a focus on ease of use, these machines are designed for straightforward operation. Minimal training is required for operators to achieve optimal results.

Portable Flange Facer Technical Information

BD-40 : Ø 48 – 255 mm (1,89” – 10,04”)

BD-50 : Ø 56 – 400 mm (2,20” – 15,75”)

BD-60 : Ø 228 – 500 mm (8,98” – 19,68”)

Ø 376 – 800 mm (14,80”- 31,50”)

LINEBORTECH Portable Line Boring Welding Machine delivers your projects on time and makes quality much easier; With our professional technical machines, you can make your sensitive operations much easier. You will confirm the quality of all the equipment we use.

Versatility in Flange Maintenance

Portable flange facing machines are not limited to specific industries. They find applications across various sectors, including oil and gas, petrochemicals, power generation, and more. Their versatility allows for the efficient maintenance and repair of flanges in different settings.

Seamless Integration with Portable Line Boring Machines

For businesses investing in machining solutions, the synergy between portable flange facing machines and portable line boring machines is evident.